PORTABLE FIRE EXTINGUISHER

Explain in Detail about all Portable extinguisher (mostly surveyor asking about CO2 and D.C.P )with cross section of it.?

Solas Regulation regarding portable extinguisher?

Weekly, monthly and Yearly maintenance on it?

Weighting of extinguisher? How you will do it?

Marking on portable extinguisher?

Solas Regulation:

-Accommodation, Service space, and Control station shall be provided with P.F.E (portable fire exit of appropriate type and in sufficient number to the satisfaction of the Administration.

-Ship of 1000 GT and above have at least 5 P.F.E.

-Total weight shall not more than 23 Kg, and capacity of fluid not less 9 ltr and not more 13.5 ltr.

-One of the P.F.E intended for use in any space shall be stowed near the entrance to that space

-CO2 P.F.E shall not be use in Accommodation.

-P.F.E shall be situated ready to use at easily visible

-P.F.E shall be provided with Device which indicate whether they been used .Spare charge shall be provided for 100% of the first 10 exti. And 50% of the remaining P.F.E ,Capable of being recharge on board. But not more than 60 total spare charge are required.More P.F.E which cant recharge on board additional P.F.E of the same quantity, type, capacity shall Be provided lieu of spare charge.

WATER TYPE ( SODA ACID TYPE) P.F.E

Working principle on =COOLING effect

Use= Carbonaceous Type A fire

Safety= Relief hole and Safety pin

Body= Solid drawn steel and internally Zinc coated

Contain= CO2 74 mg ( it will be different as per weight and capacity of Cylinder) at 36 bar pressure and Water 9 ltr minimum.

Duration of working = 6 meter jet length for 60 second

Working

-carry exti. Nearby the fire. Bring Extinguisher Towards the fire.

Remove safety pin and strike plunger to pierce the CO2 cartridge

When it will pierce the pressure created on the upper part of the container and water from the jury Hutu dicharge tube will pass and thrown as a Jet spray.

Maintenance:

===============================================

MECHANICAL FOAM TYPE

Working principle on =SMOOTHERING effect

Use= Volatile petroleum, paint, oil Type A, B fire

Safety= Relief hole and Safety pin

Body= Solid drawn steel and internally Zinc coated

Contain=CO2 74 mg ( it will different as per weight and capacity of

cylinder) at 36 bar Pressure ,A.F.F.F = 97 % and WATER= 3%

Duration of working = 6 meter jet length for 60 second

Working

-Carry exti. Nearby the fire. Keep exti Towards the fire

Remove safety pin and strike plunger to pierce the CO2 Cartridge

When it will pierce the pressure created on the upper part of the container and water from the dip tube will pass and thrown as a Jet spray.

NOTE:

-do not allow foam to strike on the surface of burning liquid.

-Direct the foam to some nearly vertical surface so that the foam runs down the side and blanket the liquid

-If you dont found any vertical surface than it is advisable to keep a distance such that the discharge from the extinguisher will fall gently on the liquid surface.

-Use same manufacture for refills and if you using pre-mix type fluid than DON’T INCREASE or DECREASE the proportion of the fluid bcoz it will affect the efficiency of the extinguisher.

Maintenance:

========================================================================

CO2 TYPE

Working principle on =SMOOTHERING effect

Use= oil, electrical, petroleum product, gaseous

Substance under enclosed space, Type B

Safety= control valve or safety valve, pressure Relief device and Safety pin

Discharge hose= NON-conductive material

Body= Solid drawn steel and internally Zinc coated

Contain=CO2 4.5 kg ( it will different as per weight and capacity o

cylinder) at 53 bar pressure

Duration of working = 3 to 4 meter length for 2 second

Pressure tested= 210 kg/cm2 prior recharge

Recharge= only at shore and when weight reduced 10% and more

Storage= should be at least 750 mm above the Floor level, it should not placed where it likely to gain heat from surrounding equipment

Process.

Working

-Carry the extinguisher near the place of fire.

-Remove the safety pin

-Direct the hose at the base of fire, starting one edge and sweeping across the surface on burning material.

-When use in open air the operator should stand up the UP-WIND side of the fire

-Fire on electrical equipment , first SWITCH-OFF the current supply.

Maintenance:

================================================

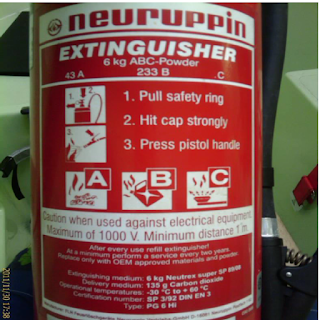

DRY-CHEMICAL POWDER TYPE

-Working principle on =SMOOTHERING effect

-Use= oil, electrical, petroleum product, gaseous substance unde

Enclosed space, Type A,B,C,D and electrical also.

-Safety= Safety pin, Relief hole in picture it will not show the inner container but there will be Inner container for CO2 Cartridge bcoz Sodium Bicarbonate will Wet freeze when it will come in direct contact with CO2 bcoz CO2 is Cool gas.

-Body= Solid drawn steel and internally Zinc coated

-Contain= inner shell CO2 60 mg ( it will different as per weight

And capacity of cylinder)

-Outer shell: 4.5 kg of D.C.P powder

DCP powder contain mixture of

SODIUM BICARBONATE + MAGNESIUM STEARATE

NaHCO3+ Mg( C18 H35 O2)2

Duration of working = 3 to 4 meter length for 20 second

Pressure tested=35 kg/cm2 prior recharge once in 3 year

WORKING:

-Carry the extinguisher to the place of fire and keep it upright

-Remove the safety pin and strike plunger. CO2 will escape to main shell and push out powder in the foam of FOG

-When using outdoor the extinguisher operate upwind side of the fire for better range.

Maintenance:

NOTE: MAGNESIUM STEARATE use for the purpose that it will not allowed to choking effect in powder.

But if choking will be there remove and replace with fresh charge.

================================================

MARKING ON EXTINGUISHER: (as per FSS code

-Name of manufacture

-Type of fire for which the extinguisher suitable

-Quantity and Type of extinguishing medium.

-Approval detail of COnstruction for use and recharge

-Year of manufacture

-Temperature range over which the extinguisher will operate

-Test pressure

Explain in Detail about all Portable extinguisher (mostly surveyor asking about CO2 and D.C.P )with cross section of it.?

Solas Regulation regarding portable extinguisher?

Weekly, monthly and Yearly maintenance on it?

Weighting of extinguisher? How you will do it?

Marking on portable extinguisher?

Solas Regulation:

-Accommodation, Service space, and Control station shall be provided with P.F.E (portable fire exit of appropriate type and in sufficient number to the satisfaction of the Administration.

-Ship of 1000 GT and above have at least 5 P.F.E.

-Total weight shall not more than 23 Kg, and capacity of fluid not less 9 ltr and not more 13.5 ltr.

-One of the P.F.E intended for use in any space shall be stowed near the entrance to that space

-CO2 P.F.E shall not be use in Accommodation.

-P.F.E shall be situated ready to use at easily visible

-P.F.E shall be provided with Device which indicate whether they been used .Spare charge shall be provided for 100% of the first 10 exti. And 50% of the remaining P.F.E ,Capable of being recharge on board. But not more than 60 total spare charge are required.More P.F.E which cant recharge on board additional P.F.E of the same quantity, type, capacity shall Be provided lieu of spare charge.

WATER TYPE ( SODA ACID TYPE) P.F.E

Working principle on =COOLING effect

Use= Carbonaceous Type A fire

Safety= Relief hole and Safety pin

Body= Solid drawn steel and internally Zinc coated

Contain= CO2 74 mg ( it will be different as per weight and capacity of Cylinder) at 36 bar pressure and Water 9 ltr minimum.

Duration of working = 6 meter jet length for 60 second

Working

-carry exti. Nearby the fire. Bring Extinguisher Towards the fire.

Remove safety pin and strike plunger to pierce the CO2 cartridge

When it will pierce the pressure created on the upper part of the container and water from the jury Hutu dicharge tube will pass and thrown as a Jet spray.

Maintenance:

===============================================

MECHANICAL FOAM TYPE

Working principle on =SMOOTHERING effect

Use= Volatile petroleum, paint, oil Type A, B fire

Safety= Relief hole and Safety pin

Body= Solid drawn steel and internally Zinc coated

Contain=CO2 74 mg ( it will different as per weight and capacity of

cylinder) at 36 bar Pressure ,A.F.F.F = 97 % and WATER= 3%

Duration of working = 6 meter jet length for 60 second

Working

-Carry exti. Nearby the fire. Keep exti Towards the fire

Remove safety pin and strike plunger to pierce the CO2 Cartridge

When it will pierce the pressure created on the upper part of the container and water from the dip tube will pass and thrown as a Jet spray.

NOTE:

-do not allow foam to strike on the surface of burning liquid.

-Direct the foam to some nearly vertical surface so that the foam runs down the side and blanket the liquid

-If you dont found any vertical surface than it is advisable to keep a distance such that the discharge from the extinguisher will fall gently on the liquid surface.

-Use same manufacture for refills and if you using pre-mix type fluid than DON’T INCREASE or DECREASE the proportion of the fluid bcoz it will affect the efficiency of the extinguisher.

Maintenance:

========================================================================

CO2 TYPE

Working principle on =SMOOTHERING effect

Use= oil, electrical, petroleum product, gaseous

Substance under enclosed space, Type B

Safety= control valve or safety valve, pressure Relief device and Safety pin

Discharge hose= NON-conductive material

Body= Solid drawn steel and internally Zinc coated

Contain=CO2 4.5 kg ( it will different as per weight and capacity o

cylinder) at 53 bar pressure

Duration of working = 3 to 4 meter length for 2 second

Pressure tested= 210 kg/cm2 prior recharge

Recharge= only at shore and when weight reduced 10% and more

Storage= should be at least 750 mm above the Floor level, it should not placed where it likely to gain heat from surrounding equipment

Process.

Working

-Carry the extinguisher near the place of fire.

-Remove the safety pin

-Direct the hose at the base of fire, starting one edge and sweeping across the surface on burning material.

-When use in open air the operator should stand up the UP-WIND side of the fire

-Fire on electrical equipment , first SWITCH-OFF the current supply.

Maintenance:

================================================

DRY-CHEMICAL POWDER TYPE

-Working principle on =SMOOTHERING effect

-Use= oil, electrical, petroleum product, gaseous substance unde

Enclosed space, Type A,B,C,D and electrical also.

-Safety= Safety pin, Relief hole in picture it will not show the inner container but there will be Inner container for CO2 Cartridge bcoz Sodium Bicarbonate will Wet freeze when it will come in direct contact with CO2 bcoz CO2 is Cool gas.

-Body= Solid drawn steel and internally Zinc coated

-Contain= inner shell CO2 60 mg ( it will different as per weight

And capacity of cylinder)

-Outer shell: 4.5 kg of D.C.P powder

DCP powder contain mixture of

SODIUM BICARBONATE + MAGNESIUM STEARATE

NaHCO3+ Mg( C18 H35 O2)2

Duration of working = 3 to 4 meter length for 20 second

Pressure tested=35 kg/cm2 prior recharge once in 3 year

WORKING:

-Carry the extinguisher to the place of fire and keep it upright

-Remove the safety pin and strike plunger. CO2 will escape to main shell and push out powder in the foam of FOG

-When using outdoor the extinguisher operate upwind side of the fire for better range.

Maintenance:

NOTE: MAGNESIUM STEARATE use for the purpose that it will not allowed to choking effect in powder.

But if choking will be there remove and replace with fresh charge.

================================================

MARKING ON EXTINGUISHER: (as per FSS code

-Name of manufacture

-Type of fire for which the extinguisher suitable

-Quantity and Type of extinguishing medium.

-Approval detail of COnstruction for use and recharge

-Year of manufacture

-Temperature range over which the extinguisher will operate

-Test pressure

No comments:

Post a Comment